Unit 5, St Georges Industrial Estate

Unit 5, St Georges Industrial EstateWilton Road

Camberley

Surrey,GU15 2QW

Tel +44(0)127 669 1463 Fax +44(0)127 668 1271

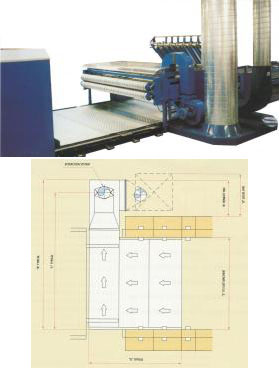

The Airdeck

The Paramount AirDeck removes board waste from rotary printer slotters

avoiding the use of problematic conveyor systems. It utilises a laminar

airflow to move offcuts to a collection point conveniently located at

the side of the machine.

Board printers have always had a problem with belt waste removal systems on rotary printer-slotters. Belts have a tendency to jam and gather waste around the rollers; the tranverse system whereby waste is transferred from one belt to another is problematic and belt tracking and maintenance are perennial problems. Very often expensive engineering work is required to build a floor pit.

The Paramount AirDeck is fitted where a wide belt conveyor would normally be. With the Paramount solution the whole area beneath the rotary die and print area is fitted with a low profile slotted deck containing pressurised air from a high efficiency fan. The fan can be sited beside the machine, or remotely if preferred. The deck itself elevates the board waste a few millimetres to transport it towards the rear of the machine. From the AirDeck discharge, it is a simple matter to extract the collected waste through an air conveying system in the usual way.

The single integrated AirDeck unit also has no moving parts in contact with the waste, meaning operators can move freely around the slotter. They can walk safely on the AirDeck to gain access to the slotter for set-up and maintenance while the deck is running.

Board printers have always had a problem with belt waste removal systems on rotary printer-slotters. Belts have a tendency to jam and gather waste around the rollers; the tranverse system whereby waste is transferred from one belt to another is problematic and belt tracking and maintenance are perennial problems. Very often expensive engineering work is required to build a floor pit.

The Paramount AirDeck is fitted where a wide belt conveyor would normally be. With the Paramount solution the whole area beneath the rotary die and print area is fitted with a low profile slotted deck containing pressurised air from a high efficiency fan. The fan can be sited beside the machine, or remotely if preferred. The deck itself elevates the board waste a few millimetres to transport it towards the rear of the machine. From the AirDeck discharge, it is a simple matter to extract the collected waste through an air conveying system in the usual way.

The single integrated AirDeck unit also has no moving parts in contact with the waste, meaning operators can move freely around the slotter. They can walk safely on the AirDeck to gain access to the slotter for set-up and maintenance while the deck is running.

- No moving parts in contact with the waste

- No belts to jam or rollers to seize

- No awkward tracking adjustments

- Virtually maintenance free

- No cleaning problems

- Can be fitted to existing machines without extensive building works

![]()