Unit 5, St Georges Industrial Estate

Unit 5, St Georges Industrial EstateWilton Road

Camberley

Surrey,GU15 2QW

Tel +44(0)127 669 1463 Fax +44(0)127 668 1271

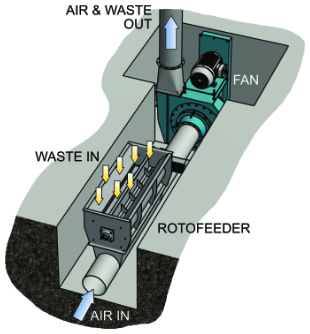

The Rotofeeder

The Paramount Roto-Feeder design replaces problematic conveyor belts

beneath production machines. Its secret lies in a regulated transfer of

waste into a single high velocity conveying duct, serving up to ten

converting machines. The waste from each converting machine is fed

through the Roto-Feeder directly into a main air duct mounted in a

floor trench below the converting machines. The conveying fan can be

located within a pit in a convenient location at the end of the row of

production machines or even remotely. The system avoids the need for

noisy fans adjacent to each production machine or belt conveyors that

can jam with waste. Roto-Feeder systems are sealed negative pressure

units that ensure all waste dust entering the system remains there, not

escaping into your plant.

Because the waste is extracted by ducted air, the Roto-Feeder system can include changes of direction, so machines can be positioned to best fit your plant layout, not forced into a straight line as with a belt conveyor. This allows the design of your plant to be simplified and space saved.

A system of Roto-Feeders on a single high capacity conveying duct can replace up to ten separate conveying fans and dust systems. This leads to substantial simplification, cost and power savings as well as reduced maintenance requirements. Conventional belt conveyors are notoriously difficult to maintain and over the years tend to suffer from poor reliability, high maintenance costs and downtime - problems which increase dramatically for longer belts. Roto-Feeders have only one slow moving part in contact with waste. These units provide maximum reliability with low maintenance requirements, allowing production machines to operate at maximum capacity, 24 hours a day. A single large diameter high power conveying duct ensures there are no blockages to the waste.

"House-keeping" dust suction points, allowing operators to efficiently remove dust from the machine, can be readily incorporated - a very useful facility paricularly within a food quality box plant.

Because the waste is extracted by ducted air, the Roto-Feeder system can include changes of direction, so machines can be positioned to best fit your plant layout, not forced into a straight line as with a belt conveyor. This allows the design of your plant to be simplified and space saved.

A system of Roto-Feeders on a single high capacity conveying duct can replace up to ten separate conveying fans and dust systems. This leads to substantial simplification, cost and power savings as well as reduced maintenance requirements. Conventional belt conveyors are notoriously difficult to maintain and over the years tend to suffer from poor reliability, high maintenance costs and downtime - problems which increase dramatically for longer belts. Roto-Feeders have only one slow moving part in contact with waste. These units provide maximum reliability with low maintenance requirements, allowing production machines to operate at maximum capacity, 24 hours a day. A single large diameter high power conveying duct ensures there are no blockages to the waste.

"House-keeping" dust suction points, allowing operators to efficiently remove dust from the machine, can be readily incorporated - a very useful facility paricularly within a food quality box plant.

- Highly reliable waste transfer

- Sealed negative pressure system avoids dust or waste leaks

- Reduces running costs

- Clear production area using one floor trench for all ancillary services

- Additional production machines can be easily added without disrupting production

- A clean working environment for a food quality production plant

![]()