Unit 5, St Georges Industrial Estate

Unit 5, St Georges Industrial EstateWilton Road

Camberley

Surrey,GU15 2QW

Tel +44(0)127 669 1463 Fax +44(0)127 668 1271

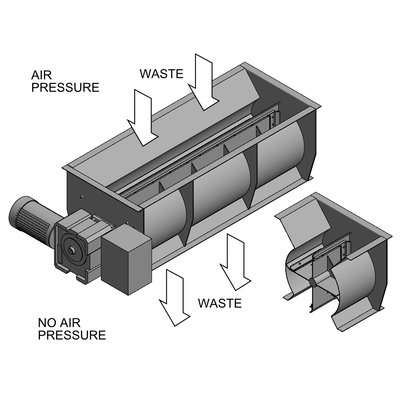

The Rotary Valve

The RotaryValve is a robust unit designed to deliver large quantities of

waste into a baler or compactor feed hopper without transfering air

pressure.

Typically Paramount waste extraction AirScreen configurations use either a rotary valve or a system balance fan to ensure zero air pressure at the material outlet. A range of noise reduction options are available where plant is located in sensitive areas.

By fitting a large capacity Paramount waste extraction Rotary Valve to the Airscreen, the unit becomes completely insensitive to any variation in system pressure. Wear-resistant seals on each of the valve's rotor blades successfully seal the entire system. This means that multiple conveying lines can feed one Airscreen, or filtration can be added without affecting the Airscreen's performance.

A further benefit is that the Compactor or Baler feed hopper is sealed from the high pressure environment of the conveying system. This ensures ideal operating conditions for this Equipment and minimises maintenance down-time.

Typically Paramount waste extraction AirScreen configurations use either a rotary valve or a system balance fan to ensure zero air pressure at the material outlet. A range of noise reduction options are available where plant is located in sensitive areas.

By fitting a large capacity Paramount waste extraction Rotary Valve to the Airscreen, the unit becomes completely insensitive to any variation in system pressure. Wear-resistant seals on each of the valve's rotor blades successfully seal the entire system. This means that multiple conveying lines can feed one Airscreen, or filtration can be added without affecting the Airscreen's performance.

A further benefit is that the Compactor or Baler feed hopper is sealed from the high pressure environment of the conveying system. This ensures ideal operating conditions for this Equipment and minimises maintenance down-time.

- No leakage of air to the compactor or baler drop chutes

- High volume of waste processed in compact units

- Can handle paper, tissue, corrugated board, aluminium foil, plastic, scrap can and flock.

![]()